Published on

August 20, 2014

Category

Features

You seen how records are mastered, now see what happens when they’re pressed.

For a music format that exists on a microscopic level, one of the most intriguing elements about the way in which records are pressed is the sheer industrial and mechanical nature of the process. From growing stampers in chemical baths to shrink-wrapping the gatefold sleeves, the pressing of a record is at every stage both an incredibly physical and exact process.

Short of inviting you all for a tour of the factory ourselves, we asked photographer Marco Walker to document the stages of how a record is pressed – with captions provided by The Vinyl Factory’s Stephen Galton – to take you up close and personal with the machines behind the music.

Photos: Marco Walker, Captions: Stephen Galton.

Metalwork baths. We grow the masters, positives and stampers in these baths via electro-plating with nickel.

A piece of metalwork before it’s put in the bath.

A piece of metalwork being placed in the metalwork bath to be electro-plated.

A ‘de-horning machine’. This spins the ‘positive’ metalwork, whilst a technician polishes the grooves. This removes all the ‘spurs’ at the top of the groove which would otherwise affect sound quality by introducing clicks if not removed.

Listening room. They listen to ‘positives’ in here to check for aural imperfections before we grow a stamper.

Miscroscope for checking groove damage.

A stamper being coated with a protective plastic film. This is to make sure no impurities get to the grooves before the record is pressed.

A centre hole being punched into a stamper.

A stamper covered with old bits of plastic.

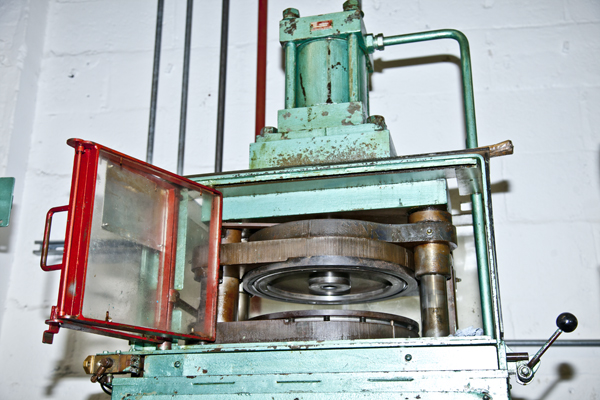

A forming machine that shapes the stamper to fit the moulds in the pressing machine.

PVC pellets that are used to make the records – that hose is sucking them up and distributing them to the machines.

Six of our pressing machines.

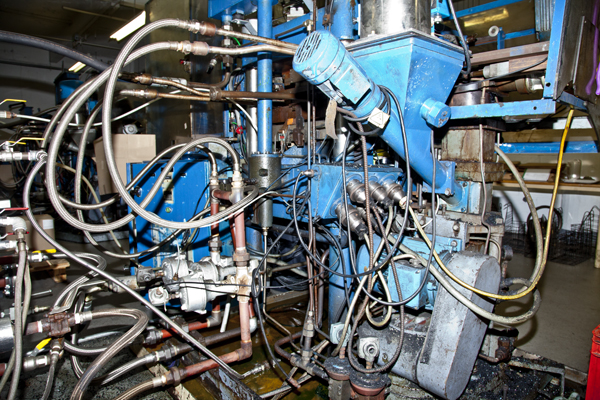

The rear of a pressing machine showing all the hydraulic cables.

A license plate from the EMI 1400 record press.

Labels.

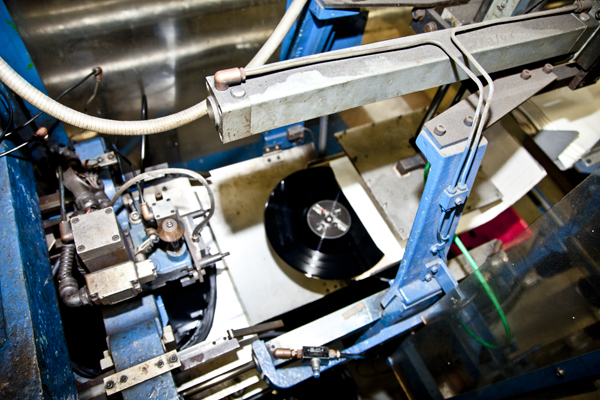

The part where labels are dropped on to the record in the pressing machine. That long thin shaft in the middle (the ‘label pin’) is what makes the centre hole in the records.

An air-gun separating record labels before they are dried in the label ovens.

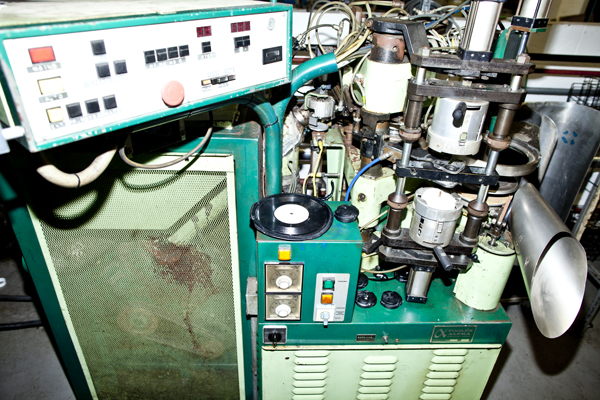

The pressing machine, showing the record being auto-packed into an inner sleeve.

‘Failed’ records ready to be recycled.

Smashing out the centre label from the failed records.

Failed records that are being crunched up to pellets again and recycled.

Buttons on the gatefold make-up machine.

Gatefolds ready to be packed.

The finished record, ready to be shipped.